Choose your car protection

We test everything. Every single item tested on Australian cars so you know that our product is best-in-class and made for Australia.

When your purchase from Dingo Trails, you are not just getting a seat cover. You are receiving hours spent on creating premium designs, investments on the latest tech and intellectual property from research and prototypes. All to give you the best car seat cover you can buy.

Every car seat cover is crafted and sewn right here in Australia. Our experienced sewing machinists are experts at what they do.

Each seat cover is individually styled with a unique design. We take cues from original seat as well as the vehicle’s heritage.

Our designers go through multiple prototypes over several months for fitting, trimming and tweaking until we are proud to put our name on it.

Designed for a perfect fit without unsightly straps or ties. Tailored to mould around the seat and stay put.

PROTOTYPE

Every seat cover is meticulously designed for a precise fit and we go through multiple prototypes until we are satisfied and PROUD to put our name on it. We check seat belt mounts, lever controls, buttons, headrest posts and fittings that are often overlooked by others. We take into consideration quality of materials, neoprene thickness, durability testing and stitch sewing.

STYLE

Simple, clean lines and elegant. Our team of designers and motor trimmers create neoprene car seat covers with a premium feel. They balance functionality and durability with style.

CHARCOAL BLACK

Dingo Trail’s Charcoal Black has been specially dyed to match most car interiors. We spent considerable effort on lab dips to strike the perfect balance of hue, tint and shade so that it’ll look perfect in your car. Not too stark against grey/light interiors yet dark enough to blend with black.

TWIN NEEDLE

Decorated with twin needle, the contrast stitch highlights our unique seat cover design in addition to accentuating the curve lines of the seat.

NO STRAPS OR TIES

Designing car seat covers for a precise fit is challenging. Our Designers go further by fitting them with no unsightly straps or ties. This is no easy task especially when there are limited fastening options. Our goal? To make neoprene car seat covers that not only look good, but are also easy-peasy to install. [1]

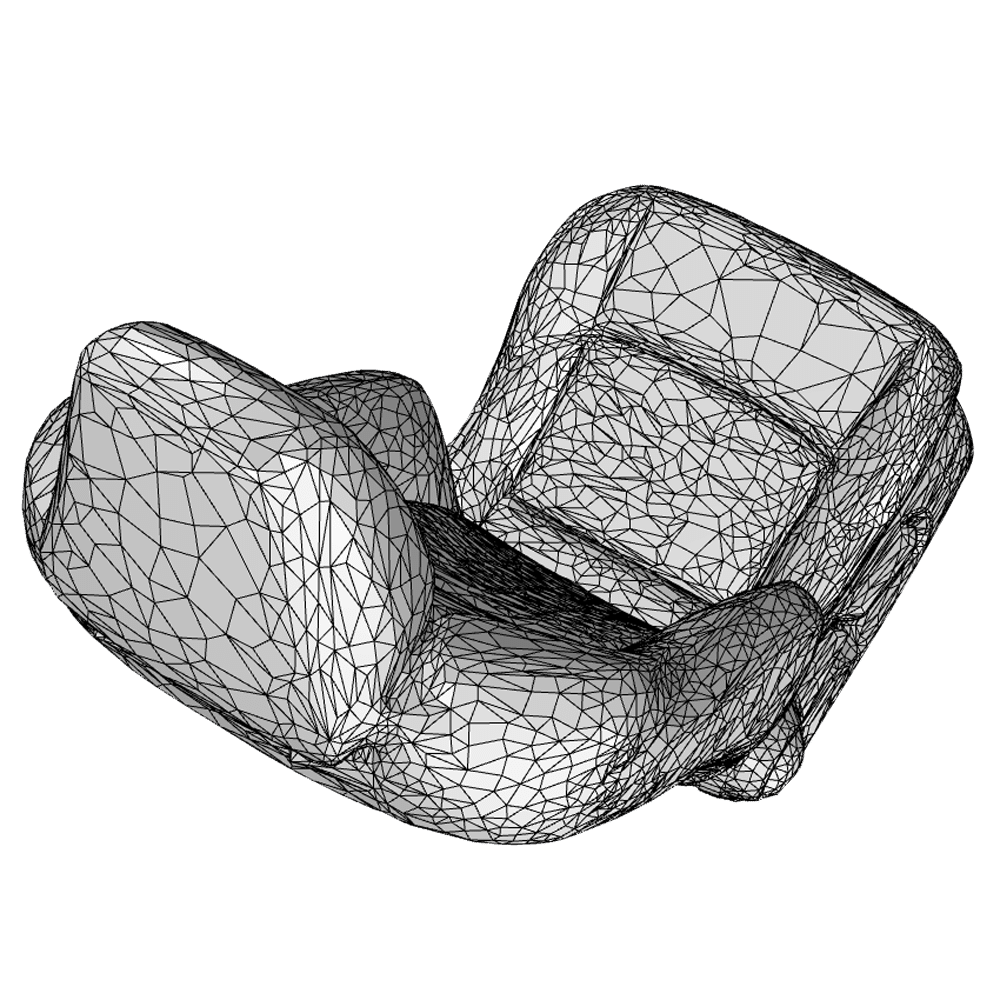

3D SCANNING

We begin by scanning the seat as a point cloud. We then clean, simplify the converted mesh and eventually, end up with a wire frame that’s ready to be converted to 2D.

3D TO 2D

The 3D wire frame is divided into pieces along edges and seam lines. Next, they are flattened and converted to 2D from which, we can start making car seat patterns.

PATTERN MAKING

This is where the magic happens. Our designers sprinkle their creative dust by adding highlights, definition and seam lines that not only accentuates, but elevates the original seat design. Every edge and angle is measured down to the millimeter for each pattern to align perfectly.

NESTING AND CUTTING

The 2D patterns are carefully arranged to fit on a sheet of neoprene while minimising wastage. They are then cut by our in-house digital cutter to within tight tolerances.

Our car seat covers not only look swish but are engineered to provide maximum versatility and protection. Full articulation of split fold, separate headrest covers, precise cutouts and more.

Combined with 3D CAD and our development in Automotive Grade Neoprene, DT seat covers don’t just look gorgeous but are practical, easy to fit, weather resistant and engineered to last. We back this up with our love it or money back guarantee.

Are easy-peasy to install with no straps or ties. Fitting Instructions included with every purchase.

Protects seat from scratches, gouges and damage. Loved by tradies. Approved by weekend warriors and outback adventurers.

Shop by

Customers appreciate precise fit, engineering and design including the subtle nuances that make our seat cover premium. Rated highly by over 7000+ customers from eBay, Google and our website. Flip slider to see unedited photos from customers and hear what they say.

More than just great looking, our car seat covers are made from durable Automotive Grade Neoprene. Sold in Australia for over 15 years, they have been proven to last.

ExploreFormulated to withstand the harsh Australian Climate.

Super soft neoprene rubber laminated with a plush knitted nylon fabric that is both luxurious yet durable.

Easily vacuum, spot clean or hose off common dirt such as crumbs, pet hairs, beach sand and general fluff. Care Instructions included with every purchase.

THE FINE PRINT

[1] No Straps or Ties – While every effort is made to design seat covers with no straps or ties, we may have some on certain models. Straps are used as a last resort due to limited fastening options.